|

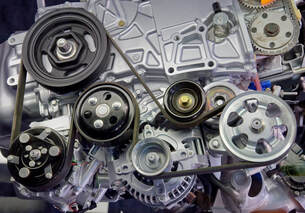

Recently, a customer came in complaining of vibrations from the wheels while driving. They previously took their vehicle to a chain shop. The shop rotated and balanced the tires, but the customer was ultimately left unsatisfied as the issue promptly returned. After a quick test drive at JAMHS Auto, the problem was obvious. The tires were not properly balanced. The cause of the tire imbalance was probably not due to any fault of the previous shop's technicians. The particular vehicle in question had cladded wheels. Cladded wheels are wheels that have aluminum rims that are coated with plastic, often chrome-colored. The plastic is relatively fragile and is easy to chip when balancing or changing tires.  Wheel mounted to balancer using precision flange plate Wheel mounted to balancer using precision flange plate Clad wheels require special tools to balance. Generally, a tire balancer will use a cone-shaped mount along with a tapered collet. While these tools work for steel and non-cladded wheels, cladded wheels require a precision flange plate that only contacts the lug holes of the rim. Without the special tools, the tire balancer may show zero, indicating the tire is fully balanced. The pressure from cone mounts can also crack the plastic, leading to the replacement of the entire wheel. If a shop doesn't have the correct precision collets and flange plates, the wheel cannot be secured tightly enough on the balancer leading to inaccurate measurements. Here at JAMHS Auto we will make sure to do the job right the first time.  The timing and serpentine belts are the two belts of concern when dealing with vehicle maintenance. The serpentine belt transmits power from the engine to various accessory components, from the power steering pump and alternator to the air conditioning and water pump. The timing belt performs a vital role in ensuring all the engine components are working together. It connects the crankshaft to the camshaft to synchronize all of the movements and prevent collisions in the engine. Signs of a bad beltIn older vehicles, it's easy to see the cracks and overall wear of the belts to assess their health. Newer belts, however, are made with more durable materials that generally will not crack. Common signs of a bad belt:

|

Archives

May 2024

Categories |

RSS Feed

RSS Feed